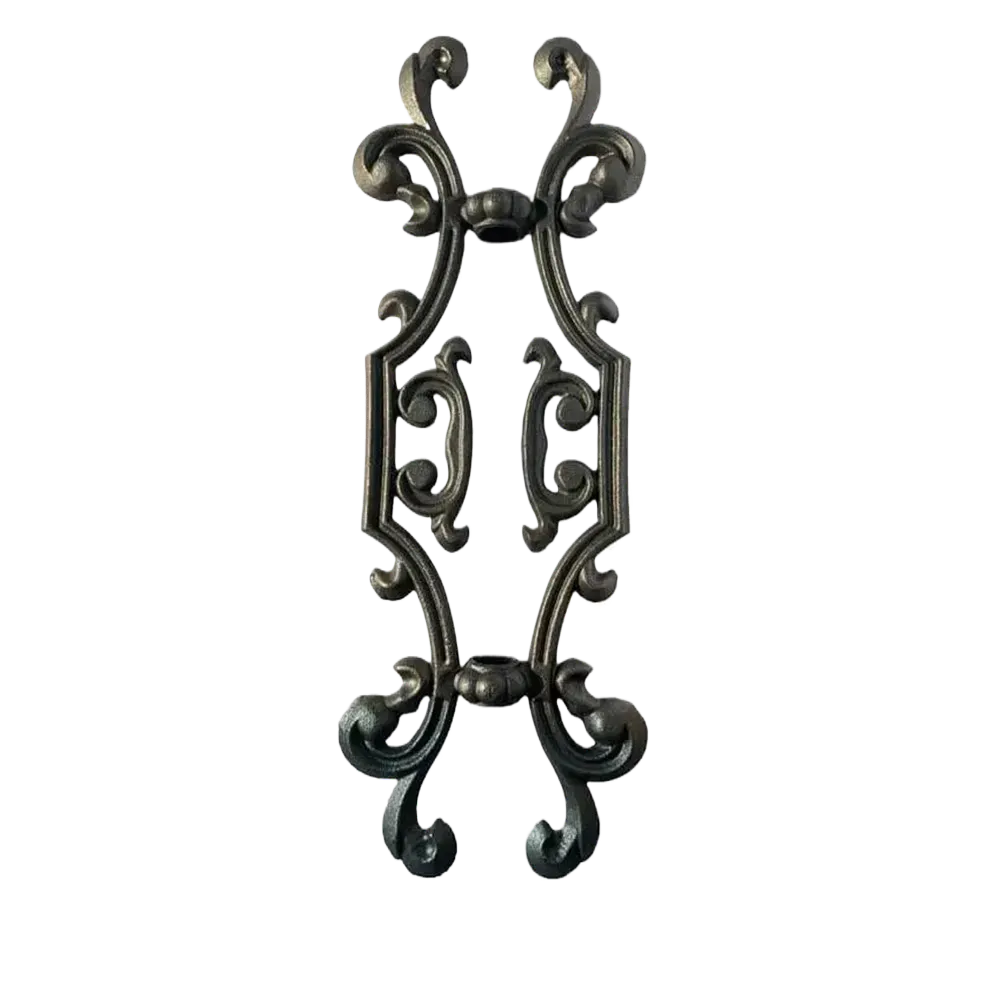

Rod iron fences have long been celebrated for their aesthetic appeal and enduring strength. Far from being merely a decorative element, these fences are constructed from a variety of components, each serving a distinct purpose. Understanding the parts of a rod iron fence can guide both homeowners and builders in making informed choices when it comes to installation and maintenance.

Even little items like the screws and bolts used can be something that makes installation a pain or detracts from the look of the fence. Make sure the hardware is color matched to your pieces and uses a stronger hex-head on the bolts that allow use of a socket. Phillips head style screws can often strip easily and make installation a pain.

- Customizable before and after installation with all of the options

True wrought iron fences are hand-shaped by blacksmiths or master craftsmen. They take time to produce and are usually custom created as needed, made to order.T3, T4, T5, T6, T7, T8 In conclusion, understanding the various parts of wrought iron fences is crucial for homeowners considering this elegant option for their property. Each component—posts, rails, pickets, gates, finials, finishes, and accessories—contributes to the overall functionality, security, and beauty of the fence. By choosing the right combination of materials and designs, homeowners can create a stunning wrought iron fence that not only meets their practical needs but also enhances the overall curb appeal of their property. This investment in quality fencing can last for decades, making it a wise and stylish choice for any property owner.

For those who prefer a more contemporary aesthetic, minimalist designs featuring clean lines and geometric shapes have become increasingly popular. These modern ornaments can blend seamlessly with contemporary architecture and landscaping, offering a sleek and sophisticated look.

Wrought Iron fences are made from the raw element of iron. Iron is a naturally occurring standalone substance that can be harvested from the earth.

- Types of Aluminium Window Frame Extrusions

- The most common type, standard rollers are typically made from steel or nylon. They are affordable and suitable for basic usage. Steel rollers offer durability but may rust over time, whereas nylon rollers are more resistant to corrosion but may wear out faster due to less durability. Both come with adjustable tension to customize the door's movement.

Typically, this layer is infused into the aluminum surface material through an electrolytic process.

- Beyond their physical attributes, long metal door handles also hold a symbolic significance

- In the realm of home decor and functionality, one innovation stands out the new roller for sliding doors. This sleek and sophisticated addition to any room not only enhances aesthetic appeal but also improves ease of use and durability.

Their commitment to sustainability is commendable, as they often use recycled aluminium in their production process, reducing environmental impact Their commitment to sustainability is commendable, as they often use recycled aluminium in their production process, reducing environmental impact

Their commitment to sustainability is commendable, as they often use recycled aluminium in their production process, reducing environmental impact Their commitment to sustainability is commendable, as they often use recycled aluminium in their production process, reducing environmental impact

From classical motifs such as scrollwork and flora to more contemporary designs, these ornaments offer a wide range of styles to suit any taste or decor From classical motifs such as scrollwork and flora to more contemporary designs, these ornaments offer a wide range of styles to suit any taste or decor

From classical motifs such as scrollwork and flora to more contemporary designs, these ornaments offer a wide range of styles to suit any taste or decor From classical motifs such as scrollwork and flora to more contemporary designs, these ornaments offer a wide range of styles to suit any taste or decor